Battery Wiring

|

|---|

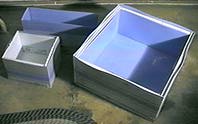

Battery Boxes

As you can see all of the battery enclosures are done and insulated except for

the long narrow one. You may also be able to see that

the larger box has an additional liner inside, which is actually just another

box like the outside one. I made this for the additional support since there will

be eight batteries for five hundred pounds of distributed weight. I haven't

decided if the lids will be transparent Plexiglass for ease of inspection or

solid, insulated panels like the rest of the box.

|

|

Before & After Cosmetic Surgery

Finally got the opportunity to practice my creative corrective

surgery techniques. The patient in the left picture was suffering from an

extruded metallic hump, not unlike the shape found for storing a spare tire.

You'll notice the clean lines and open smile in the post surgery

snapshot on the right.

I'm hiring a local welder to take care of the front and rear battery

box supports and frames. After playing around with my friends MIG welder

I decided that I didn't feel comfortable enough with my welding abilities

(nor want to spend a long time learning) to trust them in what is a major

piece of the project. I called around and found a fellow who welds and does

car body work as well. As he looked it over and talked about the options I

learned that this wasn't his first EV! He's done some body work and welding on

an Electric Truck conversion for the Town of Hanover. I feel much better

now that I have a solid plan for this section.

While he works on the welding I'm going to be starting the layout of the

control electronics. Needing to be mounted and accessible are the controller,

half a dozen relays, a fuse block, wire terminal strip(s), shunts, and the

accelerator potbox. We're also getting close to having to worry about running

cables among the battery boxes and the motor.

Battery layout & interwiring

1/28/96

The diagram above shows a rough outline of how the batteries will be laid out in the car. Eight batteries go in the rear trunk box, two of them above the motor, and the final two lengthwise where the radiator used to live.

For safety concerns I want to minimize connections where high voltages are right next to each other. All of the boxes have the main positive and negative leads come in at opposite corners. I'm not exactly sure about the lug layout on the batteries I'm getting so this may change slightly to accommodate.

The fuse in the rear battery box is a safety precaution in case something should happen to the cables or the front compartment. There are other fuses in the controller area, but this is the only one for our biggest battery section. All of the cables are heavy duty welding cable and the connecting lugs are crimped on using an aircraft hex crimper (which Bob Batson will rent out). Finally, heat shrink tubing is used to cover the exposed wire and lug junction, the lug is secured to a battery and a battery terminal cover is slipped in place.

The only outstanding issue with the batteries is the heater for warming the battery boxes during recharges in the winter. I've received a couple suggestions via email and I'll probably leave this in the to-do box for now, since I don't expect to need it until next winter. If you have suggestions (for this or other components) please drop me an email note by clicking the leaf at the bottom of the page.

1/31/96

I was going to place an order with EV America for the batteries and a bunch of other stuff but decided (at the advice of Bob) to hold off on the batteries until the very end. No reason to add a dozen batteries to the clutter in my garage while I piece everything else together. Bob suggests that the batteries and charger are the last things to buy, then once you get them hooked up and checked out you'll be ready to USE them.

In the meantime I can still order some of the other parts and start putting the electronics together.

My near term shopping list:

-

2/0 cable (black & red) for batteries and motor.

Battery lugs plus rent a heavy duty crimper and cutter

Ignition triggered relay (on/off)

Potbox

Fuse block

Wiring terminal strip

Wire (smaller guages)

Impact cutoff switch

Ammeter & Shunt for between Motor & Controller(-300 to +600 amps)

Anderson heavy guage connectors (SBX-350's & SB-50's)

Clear Vinyl Hose - protection for battery cable running under the car

Heat Shrink tubing

Next: Heavy Metal